Service Information

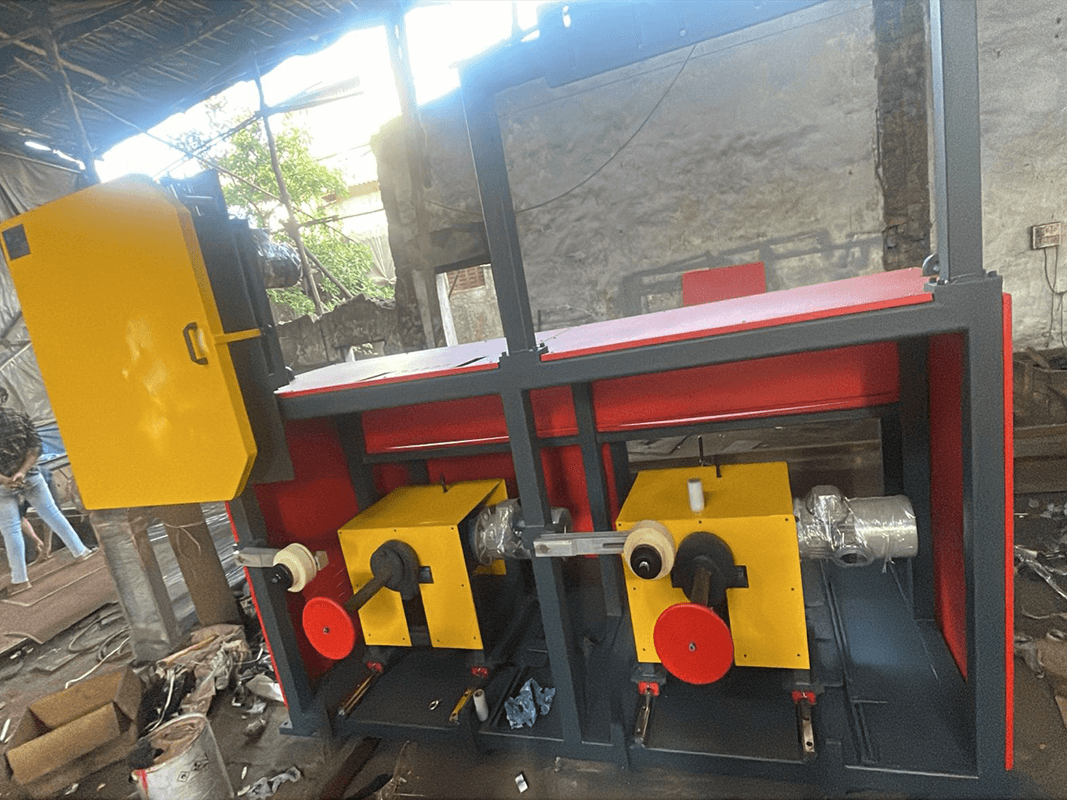

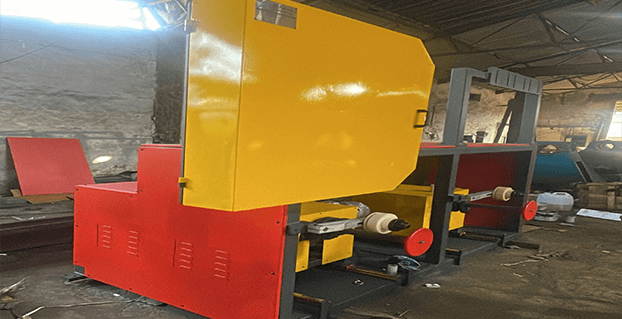

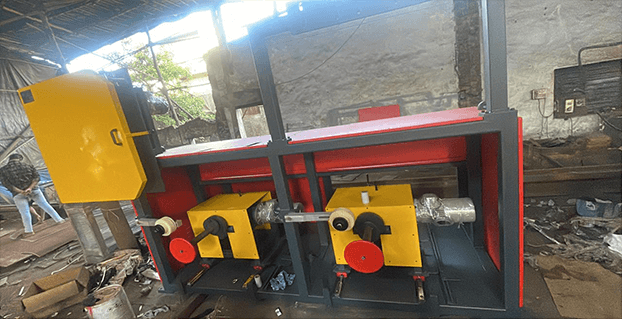

- Service Name:Dual Take Up Machine

- Category:Cable Processing & Winding Equipment

- Application:Power Cables, Armoured Cables, Control Cables, Conductor Lines

- Material Supported:GI Wires, Steel Wires, Aluminium Wires, Copper Conductors

- Configuration:Single/Dual Drum Options, AC Drive Variants, Customizable Winding System

High-Performance Dual Take Up for Smooth Cable Winding

Our Dual Take Up Machine is engineered to deliver stable, synchronized, and high-precision winding for a wide range of conductor and armouring wires. Built with a rugged steel frame and dynamic balancing, the system ensures vibration-free performance, even at higher production speeds. Its reliable control system and adjustable tension mechanism provide consistently uniform winding, making it ideal for power cable plants, conductor lines, and heavy-duty industrial applications.

Built for Accuracy, Strength & Long-Term Operation

Designed for continuous and demanding environments, the Dual Take Up offers exceptional durability through its reinforced base and robust drive system. Whether handling aluminium conductors, GI wires, or steel strands, the machine guarantees precise layer winding and smooth drum control. Optional AC drive upgrades, safety guards, and customized drum configurations enhance usability and adaptability for different cable manufacturing needs.

Key Features

- Heavy-Duty Base Structure: Maintains stability and reduces vibration during high-speed production.

- Dual Drum Synchronization: Ensures smooth and accurate winding across both take-up drums.

- Adjustable Tension Control: Supports multiple wire types with exact tension settings.

- Multi-Size Drum Compatibility: Easily adaptable for various bobbin and drum sizes.

- Precision Traverse Guide: Accurate layer winding without overlapping or distortion.

- Operator-Friendly Design: Easy controls, low maintenance, and safe working components.

- Custom Build Options: Choose drive type, drum size, automation level, and safety enclosures.